In the bustling world of product marketing, custom packaging is a silent yet powerful communicator of a brand’s identity. It’s more than just a protective layer for the product; it serves as a canvas where a brand can express its personality, values, and aesthetic ethos.

Fortunately, myriad printing techniques are available to suit your brand’s specific needs, each with unique advantages and potential applications. Whether you’re a small start-up looking to make your mark or an established brand seeking a refresh, explore different printing techniques to create the perfect custom packaging.

Offset Printing

Offset printing, or offset lithography, is a popular printing technique, particularly for larger print jobs, due to its cost-effectiveness and efficiency. Lasers burn images or text onto aluminum plates. Water and ink from separate rollers then dampen the images or text.

The areas of the plate brushed by water repel the ink, while the areas exposed to the ink transfer it onto a rubber blanket. The blanket then imprints the image onto your packaging material—be it paper, cardboard, or plastic. This indirect method results in a clean, crisp finished product, excellent for detailed graphics and large amounts of text. However, the initial setup for offset printing tends to be costly and time-consuming, making it less suitable for small orders or extremely tight deadlines.

Digital Printing

Compared to traditional methods, digital printing doesn’t require any plates, making it an ideal choice for smaller orders and projects requiring quick turnaround times. It works much like your printer at home. A digital file goes to the printer, which translates the information into fine dots of ink to reproduce your design.

The result is a high-quality image that’s exceptionally detailed and vibrant. This method allows for easy customization, as you can make changes to the digital file quickly and efficiently. However, it’s worth noting that the price per unit of digital printing is higher than offset printing, making it less cost-effective for large orders.

Flexographic Printing

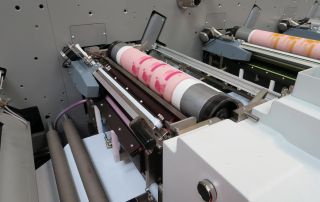

Flexography, or flexo, employs a flexible relief plate akin to a stamp. The process involves mounting the plate onto a cylinder and coating it with fast-drying ink. This plate then rolls over the packaging material, transferring the design. One of the major advantages of flexographic printing is its capacity to work with a wide array of materials, including plastic, metallic films, cellophane, and paper.

Moreover, flexo stands out for its speed and efficiency. It’s capable of producing large runs in a relatively short amount of time. However, like offset printing, the setup costs can be high, particularly for custom designs, as a new plate is necessary for each unique design.

While these are some of the most popular processes, they’re just a few of the many printing techniques for custom product packaging. At TigerPress, we dedicate ourselves to creating the perfect packaging to put the spotlight on your product, which is why we offer a wide array of custom packaging and printing services. Our experts will guide you through every option and step to ensure your packaging perfectly reflects your brand.